Questions abound after an accident. What caused the explosion? Why did the axle break? What caused the piping to fail? Oftentimes, there will be conflicting statements and opinions from witnesses, police and fire departments, insurance adjusters and professional investigators. Separating facts from speculation is critical to determining the essential details that led to a failure.

Spectrum Forensics is dedicated to bringing clarity to the analysis of complex incidents. By tailoring a range of investigative specialties to the specific problem at hand, we ensure that the team working on your project has the experience, training, and education to get the facts and convey them in a logical and understandable manner that can withstand challenges. An advanced evidence tracking system, state-of-the-art laboratory and inspection facilities, and a wide range of analytical services and resources back our commitment.

Knowing key details of code violations, material deficiencies, operator error, abnormal service environments, and other factors that may have caused or contributed to an accident can make an enormous difference in your assessment of a case. Spectrum Forensics will get you what you need to know in an unbiased, timely, and cost-effective manner.

Property Claims

Our engineers understand the pressures on insurance professionals. Spectrum engineers aim to provide an immediate, cost-effective assessment of your claim. Once on the case, we’ll contact your insured immediately and schedule an inspection to assess the situation. We’ll provide you with frequent updates to keep you apprised of the status of the investigation and to assure a cost-effective solution.

Fire/Explosion

Pipe Failures

Freeze Losses

HVAC

Large Loss Investigations

Large, complicated losses require the expertise and training of seasoned investigators. Spectrum engineers have the training and experience to manage the complex logistics, documentation, and evidence preservation critical to a successful resolution. Our large loss experience includes factory fires and explosions, industrial accidents and power generation incidents. If you are tasked with managing a large scale incident, let Spectrum help you get the job done.

Industrial Fires & Explosions

Oil & Gas Exploration and Production

Electrical Power Generation

Construction Accidents

Loss Assessment

Losses can occur in many forms. Hail can have a devastating impact on properties. Roofs, HVAC, windows, and siding are only a few of the many elements that can be impacted by hail storms. Whether it’s residential or commercial, we have the knowledge and experience to accurately assess the conditions of a property and develop a scope and cost of repair. With the ever-changing influence of local building codes, scope and costs can change dramatically when making repairs. Water can have both short- and long-term effects structures, and those impacts can be immediately apparent or take years to surface. Different building materials also vary in their response to water over time, and knowing these differences can be critical to understanding what is necessary to repair the damage. Our team understands these variances and works closely with our clients to clearly define causation and resultant damage. Fire and smoke damage are some of the most devastating events that can occur to a structure. Partial damage as opposed to a total loss can provide many complexities that can be difficult to solve. Proper evaluation of a fire event is critical to the accurate assessment of repair scope and cost. Even partial fire damage can lead to incorrect repair approaches. Code challenges and environmental concerns can drive costs up significantly. Spectrum Forensics can help manage the evaluation of losses of all sizes by getting involved early in the process.

Fire/Water/Smoke Damage

Insurance Appraisal

Water Leak

Hail Damage

Failure Analysis

The outward appearance of a failed device may obscure the root cause of the failure. A product may have been defectively designed or manufactured, but other factors such as unanticipated service environments, user abuse, or improper component selection may have played a critical role. Spectrum engineers have the experience and tools to identify the full and complete circumstances that led to the failure.

Automotive

Medical Devices

Plumbing Systems

Sporting Goods

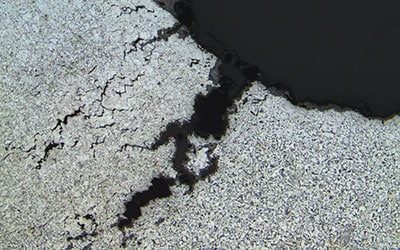

Pipelines

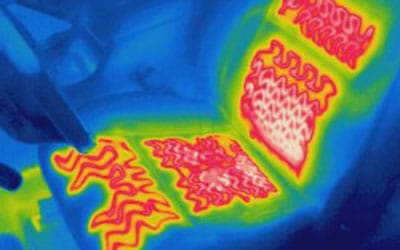

Thermal Injuries

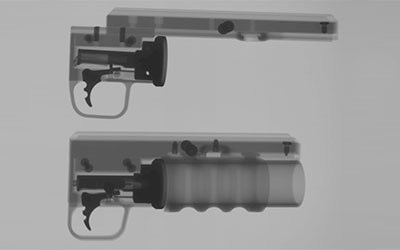

Firearms

Compressors

Laboratory Services

Experience and training must be complemented by state-of-the-art analytical tools. Spectrum engineers have on-site access to cutting edge equipment for documentation and analysis. Our laboratory facilities can host large group inspections with representatives for manufacturers, installers, service personnel, and users. Powerful analytical tools combined with high-definition documentation vividly illustrate failure mechanisms and provide a convincing basis for our engineering analysis. Spectrum also has “Virtual Laboratory” capabilities with state-of-the-art telecommunication equipment and a high-speed data link to allow remote participants anywhere in the world to participate in a laboratory examination.

Metallurgical Analysis

Electron Microscopy

Digital Microscopy

Real-time X-ray

Principal Engineers & Consultants

Carl Finocchiaro, M.S., P.E., CFI / CFEI / CVFI

Carl Finocchiaro has more than 30 years of experience in the design, testing, and analysis of mechanical systems including motor vehicle systems, consumer products, industrial machinery, safety devices, and amusement devices. He has a Master’s Degree in Engineering Management from Santa Clara University, a Bachelor’s Degree in Aerospace Engineering from Iowa State University, and is a licensed Professional Engineer in Colorado and California. Mr. Finocchiaro is an expert in fire and explosion, carbon monoxide incidents, thermal / scalding accidents, mechanical systems evaluation, water losses, and amusement rides and attractions.

Bastiaan Cornelissen, Ph.D., P.E.

Bastiaan Cornelissen has provided metallurgical consulting services to legal, industrial, and government clients since 1987. He has a doctorate in Metallurgical Engineering and Materials Science from the Colorado School of Mines and is a registered Professional Engineer in Colorado, California, and Wyoming. Failure investigations led by Dr. Cornelissen have covered pipelines, automotive components, lifting equipment, plumbing fixtures, firearms, and fastening systems. Dr. Cornelissen’s expertise includes corrosion behavior, mechanical properties, heat treating, casting, forming, bolting, and welding of a wide range of engineering materials.

Mark D. Russell, Ph.D., P.E., CFEI

Mark Russell holds a Bachelor of Science in Mechanical Engineering, a Master of Science in Nuclear Engineering, and a Doctor of Philosophy in Mechanical engineering. He is a professional engineer and is registered in 18 states.

Dr. Russell has over 30 years engineering experience in the analysis and modeling of simple and complex mechanical systems and phenomena. His experience includes work in manufacturing, product development, and engineering research. His work has included investigation of industrial fatalities, personal injuries, and property damage incidents with losses up to $100,000,000. Further, he has developed and taught improved methods for forensic engineering investigations and report writing.

He has presented at numerous technical conferences on various aspects of forensic engineering including the Russell-Jur Method. Has also presented webinars on, “How to Ask for and Get What You Need From a Forensic Engineer” and “What Should be In a Forensic Engineering Report.”

Brian D. Beatty, M.S., RE/CM

Brian has experience in cost estimating for property loss claims and his background in construction has allowed him to work on a wide variety of projects. He has been involved in the evaluation of disasters caused by fire, flood, hurricanes, earthquakes, tornados, hail/snowstorms, structural failures, and work in construction defects. He has evaluated multiple structure types, single/multi‐family residential properties, manufacturing warehouses, parking garages, hotels, office complexes, high-rise structures, and government buildings.

Reed (Kim) Bezzant

Reed (Kim) Bezzant provides our clients with specialized expertise in welding engineering, weld failure analysis, and welding safety. Mr. Bezzant has a B.S. degree in Industrial Technology (Welding Technology) from Utah State University and has held ASME Section IX Welder Certifications and AWS Certified Welding Inspector Certification. He has more than 35 years of practical experience in weld design, condition assessment, and repair in nuclear and fossil power plants, refineries, and other industrial facilities. Non-destructive inspection of welded high-energy piping and welding job site safety analysis (including fire prevention) are among his areas of expertise. Mr. Bezzant has published on weld repair and inspection procedures, and has qualified as a welding expert in several jurisdictions.

Emily B. Mitchell, M.S., CAWI

Emily Mitchell graduated from the Colorado School of Mines with a Master of Science in Materials and Metallurgical Engineering, giving her a solid background in the experimental methods and equipment used in material failure analysis investigations. Her studies focused on steel metallurgy, quality assurance standards and testing, and fracture surface analysis in the Advanced Steel Processing and Products Research Center. Ms. Mitchell has contributed to failure investigations covering medical devices, pipelines, wind turbines, automotive components, home appliances, sporting goods, firearms, and industrial equipment in addition to residential and industrial fire investigations. She is an AWS Certified Associate Weld Inspector and has a Wind Turbine Safety & Rescue Training certification.

Gene Crever, P.E.

Mr. Crever has more than 12 years of engineering experience and expertise in mechanical systems to include building systems science, industrial and mining machinery design, commercial and residential HVAC and plumbing system design. Mr. Crever holds a bachelor’s degree in Mechanical Engineering from the University of South Alabama. Mr. Crever is a professional engineer and holds licenses in 14 states throughout the western United States. He is also a Certified Fire and Explosion Investigator (CFEI). Mr. Crever has conducted hundreds of forensic investigations including materials/mechanical system failure analysis, vehicle hail damage inspections, vehicle accident reconstruction, and building science related losses.

Steve Ferry

Mr. Ferry’s career spans 33 years of commercial laboratory operations, including more than 20 years as the director of ISO-accredited independent testing laboratories. His expertise includes physical, mechanical, and hydrostatic testing of plastic materials and products. Steve has extensive expertise in the selection of analytical techniques, test methods, design of experiments, identification of unknown materials, and failure analysis of plastic products.

Contact Us

Fields marked with an * are required